When it comes to efficient, cost-effective, and reliable high-voltage power transmission, ACSR Cable stands out as an industry staple. From overhead power lines crossing vast terrains to urban electrical grids, ACSR (Aluminium Conductor Steel Reinforced) cables offer a robust solution combining strength and conductivity.

In this comprehensive guide, you’ll discover:

✅ What makes ACSR cables unique

✅ Their composition and technical properties

✅ Key specifications

✅ Real-world applications

✅ Installation and maintenance tips

✅ Expert answers to common FAQs

Let’s electrify your knowledge!

What is ACSR Cable?

ACSR Cable stands for Aluminium Conductor Steel Reinforced Cable. It’s a type of high-capacity, high-strength stranded conductor used primarily in overhead power lines.

Core Concept:

ACSR combines the lightweight, high-conductivity features of aluminum with the tensile strength of steel.Design:

It consists of a central steel core surrounded by layers of helically wound aluminum strands.Why It Matters:

This hybrid design delivers the mechanical strength needed to span long distances with minimal sag and excellent current-carrying capacity.

ACSR Cable Composition

Here’s a breakdown of its structural components:

| Component | Material | Purpose |

|---|---|---|

| Outer Layers | Aluminium | Provides excellent conductivity with low weight |

| Core | Galvanized Steel | Adds mechanical strength, prevents excessive sag |

? Did you know? The steel core can be made of single or multiple strands to customize strength for different span lengths.

Key Features and Benefits

✔️ High Strength-to-Weight Ratio

The steel core allows ACSR to handle greater tension while the aluminum keeps the conductor lightweight.

✔️ Cost-Effective Transmission

Long spans mean fewer support structures, reducing installation costs.

✔️ Corrosion Resistance

Aluminum’s natural oxide layer and galvanized steel enhance durability in harsh environments.

✔️ Versatile Customization

Different steel-to-aluminum ratios tailor the cable for various terrain and weather conditions.

Common ACSR Cable Specifications

While specs vary, here’s an overview of typical data:

| Specification | Value Range |

|---|---|

| Rated Voltage | 11 kV – 800 kV |

| Conductor Diameter | 7 mm – 40 mm |

| Tensile Strength | 15 kN – 200 kN |

| Current-Carrying Capacity | 100 A – 1500 A |

| Operating Temp | -40°C to +85°C |

Always refer to manufacturer datasheets for precise values.

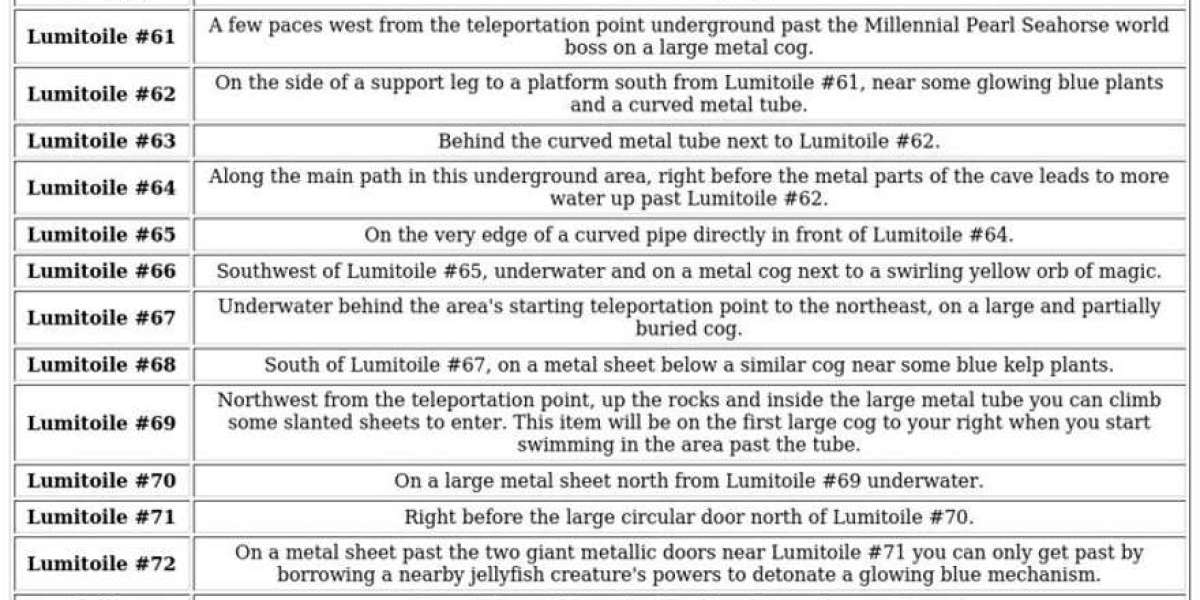

Popular ACSR Cable Sizes & Names

ACSR conductors are often named after birds and animals. Some common examples:

ACSR Dog – Medium-sized conductor for rural distribution

ACSR Panther – Widely used for high-voltage overhead lines

ACSR Moose – Extra-large for ultra-high-voltage transmission

This naming convention helps standardize designs across countries.

Applications of ACSR Cable

? Power Transmission & Distribution

Used extensively in overhead transmission and distribution networks worldwide.

? Railway Electrification

Provides a dependable power supply for rail corridors.

? River & Canyon Crossings

High tensile strength makes ACSR ideal for long spans over challenging terrain.

? Renewable Energy Projects

Wind and solar farms depend on ACSR for grid integration over wide areas.

Installation Tips for ACSR Cables

✅ Sag & Tension:

Careful calculation of sag and tension ensures proper performance under varying temperatures.

✅ Handling:

Avoid excessive bending or kinking to maintain conductor integrity.

✅ Joints & Terminations:

Use compression joints and fittings designed for ACSR’s unique bimetallic structure.

✅ Corrosion Protection:

Apply protective greases or coatings if installed in highly corrosive environments.

Maintenance Best Practices

Regular Inspections: Check for broken strands, corrosion, and connector wear.

Thermal Scans: Identify hotspots or unusual resistance.

Retensioning: As cables age, periodic retensioning can minimize excessive sag.

Technical Advantages Over Other Conductors

Here’s a quick comparison with alternative conductors:

| Property | ACSR | AAAC | ACAR |

|---|---|---|---|

| Conductivity | High | Very High | High |

| Tensile Strength | Very High | Medium | High |

| Weight | Moderate | Low | Moderate |

| Corrosion Resistance | Good | Excellent | Excellent |

| Cost | Cost-Effective | Higher | Higher |

Environmental Considerations

Modern ACSR cables are manufactured with sustainability in mind:

? Recyclability:

Both aluminum and steel components are fully recyclable, supporting circular economy goals.

?️ Climate Resilience:

Engineered to withstand extreme temperatures, wind loads, and ice accumulation.

FAQs About ACSR Cable

❓ What’s the difference between ACSR and AAAC?

Answer: ACSR has a steel core for added tensile strength, ideal for longer spans. AAAC (All Aluminium Alloy Conductor) has no steel core, offering better corrosion resistance in coastal regions but with slightly lower tensile strength.

❓ How long does an ACSR cable last?

Answer: When installed and maintained correctly, ACSR cables can operate reliably for 40–60 years, depending on environmental factors.

❓ Can ACSR be used underground?

Answer: No, ACSR is primarily designed for overhead lines. For underground installations, armored cables with different insulation and moisture barriers are used.

❓ Is there any risk of galvanic corrosion in ACSR?

Answer: Proper galvanization of the steel core minimizes galvanic corrosion. Additionally, manufacturers may apply protective grease between the aluminum and steel layers for extra protection.

❓ How do I select the right ACSR size?

Answer: Selection depends on voltage level, span length, load current, environmental conditions, and national standards. Consult with certified electrical engineers or follow utility design guides.

Quick Tips for Choosing a Reliable ACSR Cable Supplier

✔️ Look for certifications such as ISO and IEC compliance.

✔️ Verify that raw materials meet industry standards.

✔️ Request performance test reports.

✔️ Confirm experience in large-scale power projects.

✔️ Ask about custom design capabilities for unique spans or terrains.

Key Takeaways in a Snapshot

ACSR Cable blends strength and conductivity for overhead power lines.

Reinforced steel core reduces sag and extends span capability.

Widely used in urban grids, rural areas, railways, and renewables.

Proper installation and periodic maintenance ensure decades of reliable service.

Always source from reputable manufacturers for guaranteed performance.